Our expertise encompasses a multitude of concrete mixtures that we engineer and qualify for the specified performance and constructability. Along with “conventional” normal and lightweight concrete with a wide range of strength and permeability classes we develop and qualify specialty mixture types, among them:

- High-performance

- Rapid hardening and ultra-rapid hardening

- Non-shrink (K-cement and shrinkage-compensating additives)

- Cellular low density (25-65 pcf)

- Heavyweight (180-300 pcf)

- Pervious

- Roller-compacted

- Underwater

- Self-consolidating

- Architectural (discoloration resistant; simulating natural environments; sculptural), and others.

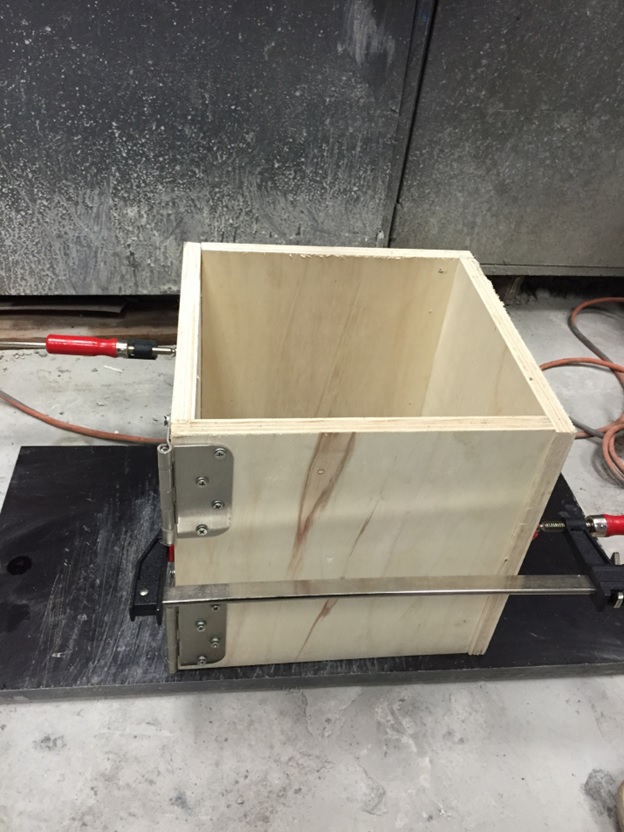

Our laboratories are equipped to evaluate properties of fresh concrete affecting constructability, such for example as the formability of low-slump pavement mixtures intended for slip-forming, segregation resistance of self-consolidating concrete, bleeding, setting time, and others. We qualify concrete for compressive, flexural, direct, and splitting tensile strengths, Poisson ratio and modulus of elasticity, creep, shrinkage, coefficient of thermal expansion, cracking resistance, rapid chloride permeability, coefficient of chloride diffusion (ASTM & EN), bulk resistivity, adiabatic temperature rise, and other physical properties. Our laboratories are equipped for simulating the production, consolidation, and curing of cast-in-place and precast concrete. We use various types of mixers (drum mixers, pan mixers, high-speed shear mixers), external and internal vircators, steam curing chambers, temperature-control and temperature-matching curing chambers, foam generators for cellular concrete, and other specialized equipment.